CaaS – GLOBAL PIONEERS

CaaS (Cooling-as-a-Service) ≫

EPC (Engineer/Procure/Construct) ≫

Engineering Consulting ≫

Service & Maintenance ≫

We impact the life cycle cost of the global cold chain to deliver food, health and information security for all.

We are a global pioneer of Cooling as a Service (CaaS).

Through CaaS, we deliver high-performance, energy-efficient cooling with no capital investment required from our clients.

We design, fund, build, operate, and maintain refrigeration systems while clients benefit from guaranteed temperature and efficiency, for the full duration of the contract.

CaaS shifts clients’ operational and financial risk of owning and running industrial refrigeration systems to us.

CaaS

- We remove the risk of owning and operating refrigeration systems from end-users

- We invest 100% of capital required

- We take refrigeration systems off-balance sheet

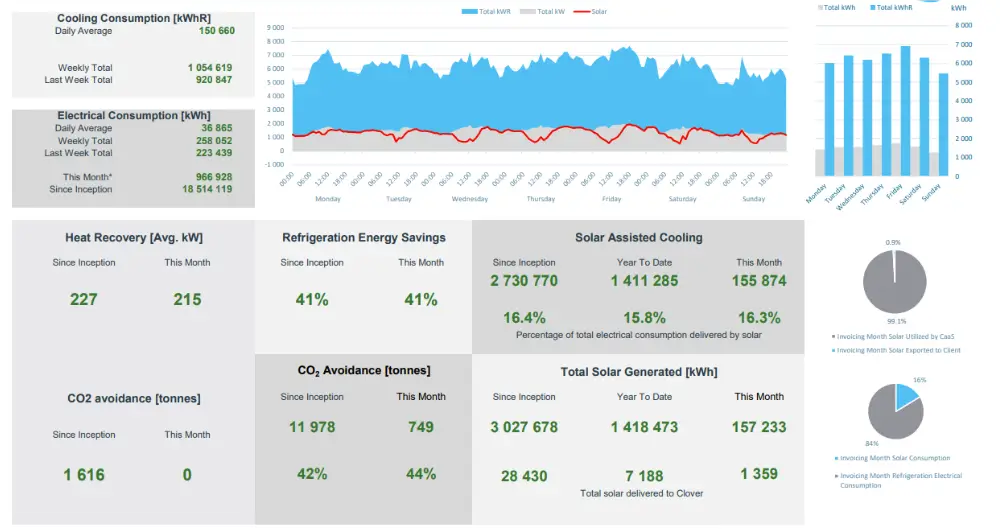

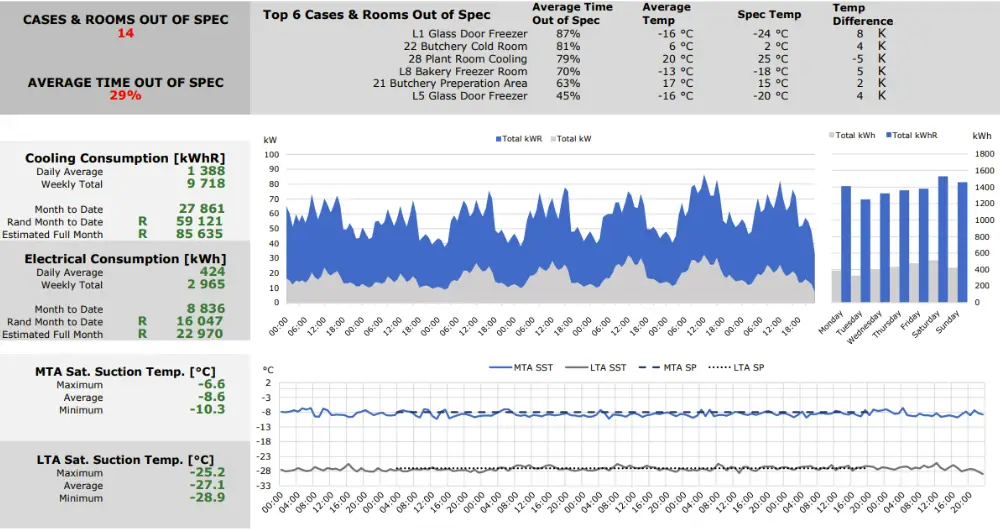

- We measure refrigeration efficiency (coefficient of performance or CoP) through our EP Cooling Meter

- We guarantee temperature and energy efficiency for the full duration of the CaaS contract

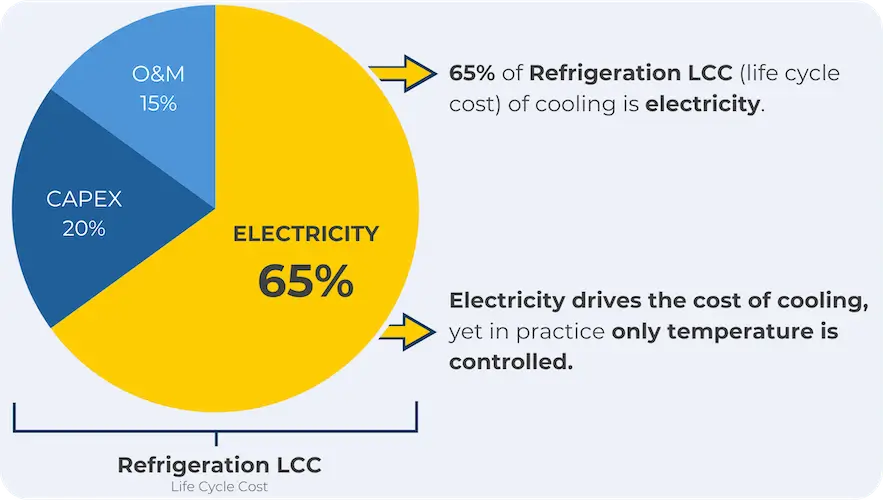

For lowest Refrigeration Life Cycle Cost:

- Guarantee Temperature and

- Guarantee efficiency (CoP)

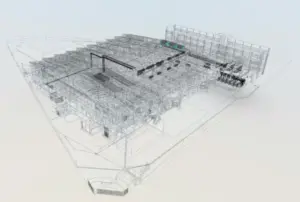

CaaS integrated value chain

- System design and costing

- Accurate digital twin models (to predict efficiency and throughput)

- Techno-economic model

- Project finance and investment

- Project contracting

- Project build and commissioning

- Service and maintenance

- Cooling Meter

- 24/7 alarm monitoring and performance optimisation

Shift operational and financial risk to Energy Partners

CaaS Summary

- Reduce operational risk to 0%

- Free up capital

- Ensure lowest cost for maximum cooling – guaranteed

EPC – Integrated and tailored

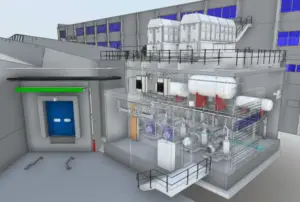

- We develop natural refrigerant projects: Ammonia and CO2

- Our in-house design and engineering team is experienced in delivering the most cost-effective solution possible in terms of life cycle costing

- We do not outsource construction risk – guaranteed

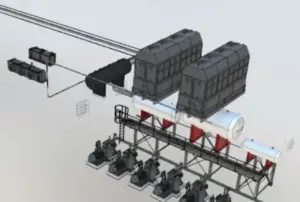

Refrigeration Engineering Consulting – we balance cost, performance and environmental responsibility

- 25 years’ experience

- Natural refrigerant specialists: Ammonia and CO₂ systems

- Post-harvest refrigeration: Handling and treatment of fresh produce

- Industrial refrigeration: Process cooling, ventilation and climate control

- Industrial HVAC design: Food processing, high-risk areas and drying facilities

- System efficiency modelling: Software utilised to generate digital twins to simulate optimal plant solutions

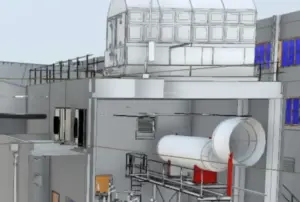

Service & Maintenance – 24/7, countrywide

- 25 skilled teams

- Corrective maintenance

- Preventative maintenance

- Predictive maintenance

- Compliance: SAQCC, SANS10147, PER

- Weekly dashboards tracking performance, efficiency and energy consumption