Reduce Operational Risk

Steam Outsourcing ≻

BOILER SALES (New & Refurb) ≻

Boiler Rental ≻

Services ≻

Burners ≻

Boiler Spares ≻

We drive sustainable industrial growth by providing trusted heating solutions that minimise environmental impact.

Steam Outsourcing

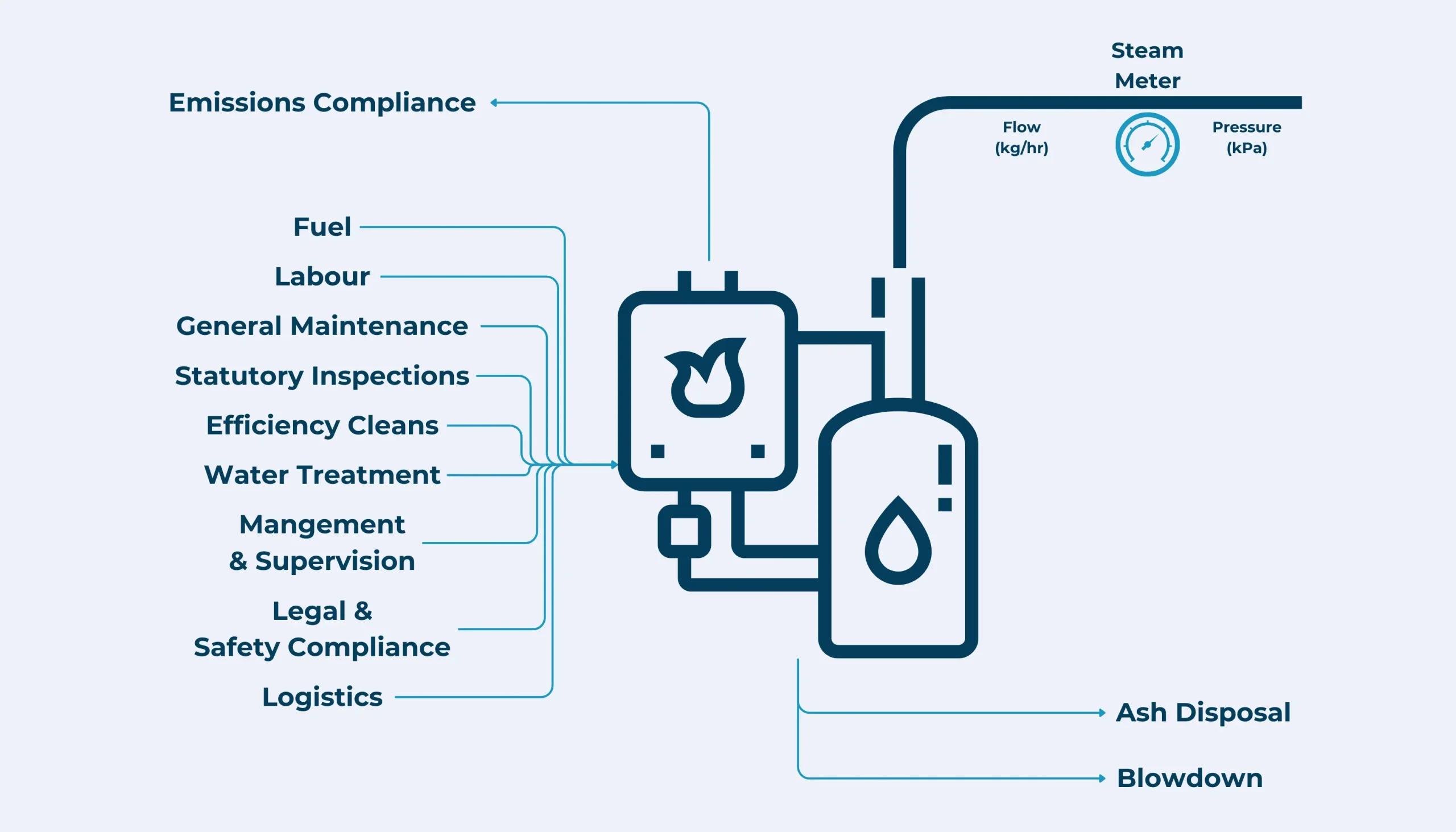

Shift operational and financial risk of steam supply from clients to us:

- 100% off-balance sheet

- Improved efficiency

- Increased uptime

- Improved emissions

- Lower carbon footprint

- Lower overall cost

- Scalable – up or down – as needs change

- Assurance of regulatory compliance

We provide cutting-edge steam outsourcing solutions and fully integrated cooling installations to industries such as food processing and manufacturing.

- We offer end-to-end outsourced steam solutions, from the design and installation of infrastructure to ongoing O&M

- We use innovative technology and best practices to ensure consistent steam supply, minimised disruptions, reduced operational costs and a reduced carbon footprint

- We prioritise eco-friendly solutions for steam generation that is both efficient and sustainable

- Our unique outsourcing model frees up capital expenditure, alleviates operational risk, and directs client resources toward core operations.

Boiler Sales

We supply a full range of new and refurbished boilers for purchase, short- and long-term hire.

New Boilers for Sale:

- Value-driven pricing

- Modern designs from top manufacturers provide better fuel efficiency and reduced emissions

- Wide range of fuel options: Coal, HFO, LFO, Gas, Biomass

- ISO 3831 / ISO 9001 accreditation

- 24/7 maintenance support.

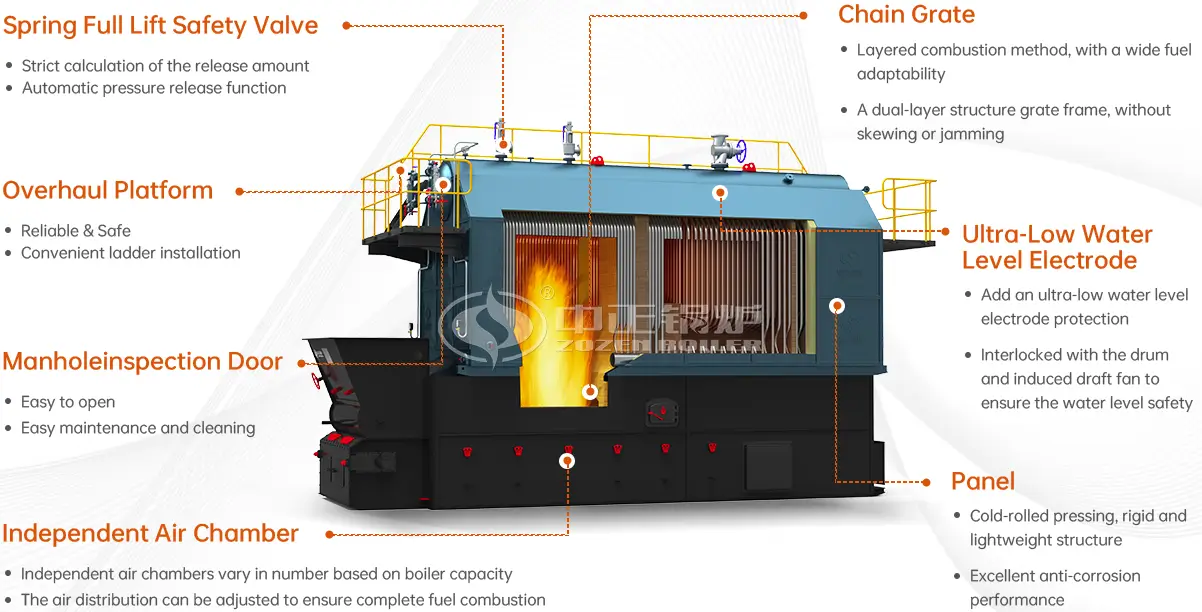

Energy Partners is the proud channel partner of Zozen boilers. The best suited coal fired boiler for the South African market is the SZL water tube boiler, due to its ability to efficiently burn coal ranging from grade A down to grade D. This important feature mitigates the risk of declining quality and availability of high-grade coal in SA, a trend that is set to accelerate due to underinvestment in new coal mines.

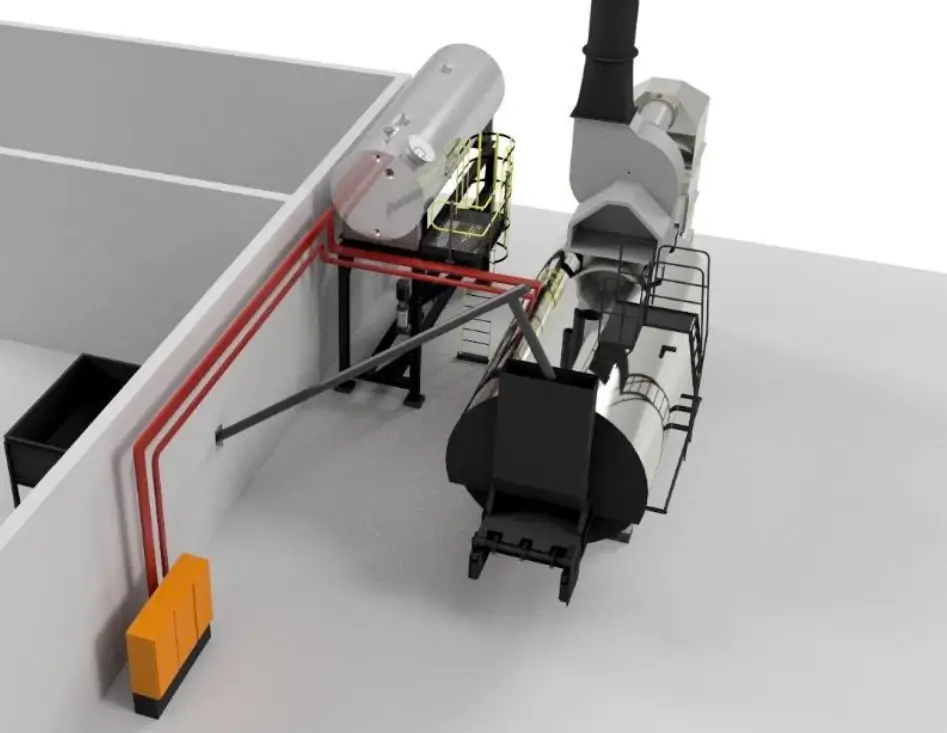

The SZL series boiler is a horizontal, dual-cylinder, chain grate boiler designed for steam and hot water. This series meets international standards (ASME) for technology, performance and environmental protection. It combines the advantages of package boilers, featuring a compact structure, single-story shop layout, easy installation, short construction period, low cost, and simple operation.

All Zozen boilers are controlled by Energy Partners’ Optiflame Control System. The system includes remote monitoring and [[…?]] (put this on the page, I will find our from the team what text is missing)

Cochrane Engineering

Cochrane Engineering

Cochrane Engineering has been manufacturing boilers for over 65 years, providing top-quality machinery for businesses in a variety of industries. Cochrane boilers are reliable, efficient and durable, ensuring that clients can focus on their business operations without worrying about equipment failures or downtime. Contact us for more information, including Waste Heat Boilers.

The VAPOPREX HVP is a saturated steam boiler with three flue passes, two of which in the combustion chamber, for the combustion of liquid or gaseous fuels in a pressurized furnace.

RSW N Hot Water boiler series

Hot water generator with pressurised combustion, ready for operation in combination with a jet burner on liquid or gas fuel. Completely cooled combustion chamber, sized to ensure low heating loads. Furnace with flame reversal and low heating load. Range consisting of 18 models with rated outputs from 92 to 1,890 kW.

Refurbished Boilers for Sale:

We offer refurbished boilers to clients seeking cost effective solutions that don’t compromise on performance

- An economic alternative with no compromise on performance

- Wide range of fuel options: Coal, HFO, LFO and gas

- Rigorous quality checks and necessary upgrades to meet industry standards

- ISO 3831/ISO 9001 accreditation

- 24/7 maintenance support

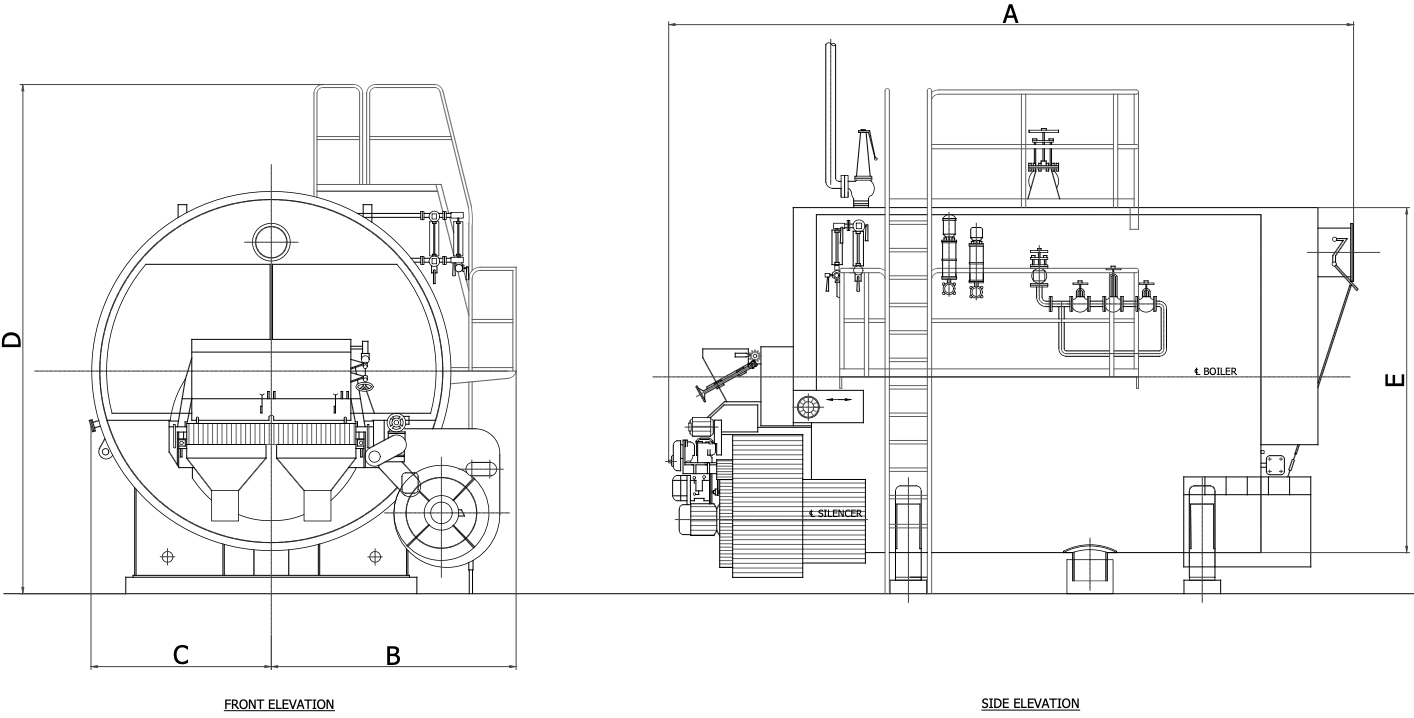

Zozen SZL Specs

Model

Rated steam

capacity (t/h)

Rated working

pressure (MPa)

Rated steam

temperature (℃)

Thermal

efficiency (%)

Max transport

dimension (m)

SZL6-1.25-AⅡ

6

1.25

194

>80

6.20×2.80×3.65

7.40×2.70×2.40

SZL6-1.6-AⅡ

6

1.6

204

>80

6.20×2.80×3.65

7.40×2.70×2.40

SZL6-2.5-AⅡ

6

2.5

225

>80

6.20×2.80×3.65

7.40×2.70×2.40

SZL8-1.25-AⅡ

8

1.25

194

>80

7.80×3.25×3.61

8.25×3.10×2.80

SZL8-1.6-AⅡ

8

1.6

204

>80

7.80×3.25×3.61

8.25×3.10×2.80

SZL8-2.5-AⅡ

8

2.5

225

>80

7.80×3.25×3.61

8.25×3.10×2.80

SZL10-1.25-AⅡ

10

1.25

194

>80

7.80×3.25×3.61

9.00×3.10×2.80

SZL10-1.6-AⅡ

10

1.6

204

>80

7.80×3.25×3.61

9.00×3.10×2.80

SZL10-2.5-AⅡ

10

2.5

225

>80

7.80×3.25×3.61

9.00×3.10×2.80

SZL12-1.25-AⅡ

12

1.25

194

>80

8.80×3.52×3.65

8.40×3.10×2.80

SZL12-1.6-AⅡ

12

1.6

204

>80

8.80×3.52×3.65

8.40×3.10×2.80

SZL12-2.5-AⅡ

12

2.5

225

>80

8.80×3.52×3.65

8.40×3.10×2.80

SZL15-1.25-AⅡ

15

1.25

194

>80

9.65×3.28×3.60

10.70×3.30×2.80

SZL15-1.6-AⅡ

15

1.6

204

>80

9.65×3.28×3.60

10.70×3.30×2.80

SZL15-2.5-AⅡ

15

2.50

225

>80

9.65×3.28×3.60

10.70×3.30×2.80

SZL20-1.25-AⅡ

20

1.25

194

>80

10.65×3.28×3.60

10.30×3.81×2.80

SZL20-1.6-AⅡ

20

1.60

204

>80

10.65×3.28×3.60

10.30×3.81×2.80

SZL20-2.5-AⅡ

20

2.5

225

>80

10.65×3.28×3.60

10.30×3.81×2.80

SZL25-1.25-AⅡ

25

1.25

194

>81

11.65×3.80×3.60

10.30×3.81×2.80

SZL25-1.6-AⅡ

25

1.6

204

>81

11.65×3.80×3.60

10.30×3.81×2.80

SZL25-2.5-AⅡ

25

2.50

225

>81

11.65×3.80×3.60

10.30×3.81×2.80

SZL30-1.25-AⅡ

30

1.25

194

>81

10.00×3.36×3.60

SZL30-1.6-AⅡ

30

1.6

204

>81

10.00×3.36×3.60

SZL30-2.5-AⅡ

30

2.5

225

>81

10.00×3.36×3.60

SZL35-1.25-AⅡ

35

1.25

194

>81

10.00×3.65×3.85

SZL35-1.6-AⅡ

35

1.6

204

>81

10.00×3.65×3.85

SZL35-2.5-AⅡ

35

2.5

225

>81

10.00×3.65×3.85

Refurbished Boiler Stock (immediately available)

Ref No.

Make

COAL FIRED

Kg/hr

WOOD FIRED

Kg/hr

Model

Pressure

438

1800

1080

12-018

750 kPa

453

1800

1080

12-018

750 kPa

445

2500

1500

431

1000 kPa

430

2500

1500

431

1034 kPa

371

Avelin Bradford

3300

1980

AV33

800 kPa

437

6300

6300

391

1034 kPa

451

10 000

6000

19-100

960 kPa

452

10000

6000

491

1034 kPa

450

14 545

8700

2H320

1034 kPa

339

20 000

11 500

29-200

870 kPa

470

14 545

11 500

29-200

1034 kPa

471

20 000

11 500

492

960 kPa

472

16 000

9200

28-160

960 kPa

473

14 545

8700

2H320

1034 kPa

474

14 545

8700

2H320

1034 kPa

445

2500

1500

431

1000 kPa

423

2800

1600

B63

1034 kPa

299

Long Chuan

4200

2520

LC6

1000 kPa

304

5000

N/A

ERK050

1200 kPa

475

7500

4500

P160

1034 kPa

399

11 500

11 500

29-200

870 kPa

411

13 500

13 500

TM3000

1500 kPa

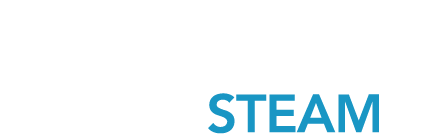

Cochraine MK7 Specs

Boiler Rental

Maintain your facility uptime during all shutdowns with the EP hire boiler fleet. The deployment can be tailored to suit the site requirements up to a complete independent system, which is operated by Energy Partners.

- Diverse range of boilers available for both short- and long-term hire, ranging from small, portable boilers to large industrial units

- Full installation, monitoring, maintenance and decommissioning services available

- Flexible contracts that cater to evolving client needs, such as extended hire periods or changing capacity

- Maintained to the highest standards to ensure optimum performance

- 24/7 maintenance support with rapid response deployment during emergencies.

Energy Partners can include a range of optional accessories:

- Fuel storage tanks

- Gas trains

- Feed water storage tanks

- Water treatment plants

- Diesel generators

- Boiler operators

Rental Boiler Stock (immediately available)

Ref No.

Capacity

(Oil/Gas)

Pressure

Model

Dimensions

WxLxH

Transport Weight

439

6300 kg/hr

1400 kPa

C13800

2400 x 6300 x 2800

20

441

6300 kg/hr

2600 kPa

M063

3000 x 7000 x 3400

25

442

8000 kg/hr

2800 kPa

TM800

3000 x 7000 x 3400

28

462

12 000 kg/hr

1034 kPa

TM1200

3000 x 7700 x 3600

28

443

14 545 kg/hr

1895 kPa

P320

3800 x 7500 x 4200

45

416

20 000 kg/hr

2000 kPa

SMK7

4000 x 7000 x 5000

61

400

30 000 kg/hr

1200 kPa

SMK7

4600 x 7700 x 5000

68

Services

Join the growing list of satisfied customers and experience exceptional service and unwavering commitment to quality.

Steam Plant Services

We have built a reputation as a leader in steam plant innovation by consistently delivering technical expertise and on-time project management to solve challenging engagements. As an international provider of boiler and steam plant services we can source, install, repair, replace, maintain, and ship boiler solutions anywhere in Southern Africa, 24 hours a day:

- 24/7 Service

- Boiler conversions to preferred fuel usage

- Major and minor boiler equipment repair

- Ad-hoc, 12, and 36 monthly statutory inspections

- Scheduled open, clean and close services

- Tube replacement

- Refractory repair

- Total steam plant installations

- Stokers

- Grit arrestors

- Coal and ash handling equipment

- Steam trap installation and replacement

- Equipment upgrades and retrofits

Combustion Projects/Services

The combustion service division is well-versed and experienced in all areas of combustion maintenance, capable of pinpointing common combustion start-up problems for solid, liquid, and gas-fuel boiler systems. We provide further comprehensive combustion services, ensuring optimal performance and safety of combustion systems throughout Southern Africa:

- 24/7 Service

- Boiler efficiency optimisation

- Boiler safety verification

- Combustion and safety maintenance contracts

- Troubleshooting common startup problems for boilers

Burners

EPS can recommend and install a new burner system to help you achieve peak boiler efficiency and dependability. We specialise in burner efficiency upgrades for all combustion systems, including heaters, kilns, dryers, furnaces, and boilers. We also offer conversions of coal-fired boilers to natural gas and/or fuel oil. Our comprehensive service includes design engineering, equipment procurement, removal of existing systems, installation of upgraded burners, and full system start-up:

- 24/7 service

- Diverse range of burners spanning various sizes, applications, and fuel types

- Designed to maximize energy efficiency, reducing fuel consumption and operating costs

- Lower emissions and reduced environmental impact with cleaner combustion technology

- Reliable brands that ensure minimized downtime and production losses

- We are authorized agents for industry-leading brands like Unigas and Greens Combustion, and trusted supporters of other popular burner brands like Limpsfield and Hamworthy

Unigas

Today, full compliance with emission standards is no longer sufficient to prevent the “greenhouse effect.” Thanks to its “Zero Emission NOx” research project, CIB Unigas is playing a proactive role in discovering new technologies to create the most environmentally-friendly products possible.

Key Features

- Wide range of burners from 15 to 70,000 kW

- Custom-made burners to meet specific requests

- Suitable for single fuel, dual fuel, and multi-fuels.

- Known for low NOx emissions, high turndown ratios, and easy maintenance

- Fuel savings of 10-35% due to high combustion efficiency and low O2 performance

- Total boiler house solutions using 2D and 3D AutoCAD

Quality Assurance

- Certified by German TÜV

We are the exclusive representative and distribution partner of Unigas burners in Southern Africa, supplying all capacities and covering all fuels.

Unigas - Small/Medium Burners (19kW to 2050kW)

Unigas - Medium/Large Burners (480kW to 80MW)

Unigas - Industrial Burners

Greens Combustion

Greens Combustion is a UK company with extensive experience and global references, supplying a complete range of burners and other combustion systems to various industry sectors, including reforming, petrochemical, fertilizer, and power generation.

Key Features

- Advanced technology ensures high-performance, low-noise and low-fuel-consumption burners

- Suitable for a wide range of applications, including kilns, incinerators, refineries, top-fired reformers, radiant wall furnaces, and EDC crackers

- Ideal for clients requiring high-temperature and high-pressure combustion

We are the exclusive Southern African representative and distribution partner of Greens Combustion process burners, including Airoil flaregas systems, floor burners, radiant wall burners, and down-fired burners.

Limpsfield

Limpsfield offers extensive experience in commissioning and reducing O2 levels in combustion for firetube, watertube, and furnace applications. The burners are designed to maximize efficiency, reduce fuel usage, and minimize the carbon footprint.

Key Features

- Total boiler house solutions using 2D and 3D AutoCAD

- Suitable for single fuel, dual fuel, multi-fuel, and waste stream fuels

- Low NOx burners for both gas and oils

- Industrial forced draught design suitable for alternative or simultaneous firing of gaseous and mineral fuel oils.

- Fuel savings of 10-35% due to high combustion efficiency and low O2 performance

Quality Assurance

- UL and CE approved

- ISO9001:2008 certified

- CE BS EN 676 certificate for design, build, and testing

Burner Spares

We maintain a comprehensive range of high-quality, critical industrial burner spare parts for various burner makes and models, ensuring that our clients have the components they need to keep their operations running smoothly:

- Ignition electrodes

- Burner nozzles

- Flame sensors

- Control boxes

- Fuel pumps

- Air pressure switches

- Burner motors

- Oil filters

- Gas valve

Exclusive partner of CPF Industriale, Geca, and Tecnocontrol in Southern Africa:

- Regulates gas pressure and flow for a stable and consistent supply of gas to burners, boilers, or heaters.

- Filters gas quality, removing impurities or contaminants that could damage the equipment or affect combustion.

- Protects gas systems from overpressure and under-pressure, preventing accidents or malfunctions.

- Suitable for various applications, such as burners, boilers, heaters, furnaces, ovens, dryers, and generators.

- Saves energy and reduces emissions by ensuring optimal combustion and minimizing gas wastage.

Burner Combustion Control

We provide EP proprietary advanced combustion solutions tailored to improve efficiency and reduce emissions. Our expertise includes:

- Supply of proprietary coal combustion systems

- Installation and commissioning

- Performance optimization

We offer custom design/build PLC control systems for boilers and system processes, as well as complete plant startup and troubleshooting. With remote access to customers’ boiler control systems using advanced technologies, we analyse customer issues and create solutions without an on-site visit:

- System assessments

- Custom programming

- FAT testing

- Gas testing & calibration

- Equipment installation

- Commissioning

- Monitoring

- Maintenance

- Upgrades

- Boiler instrumentation

Burner Controls

Integrating a boiler control system is one of the highest-impact, lowest-cost solutions for increasing boiler efficiency. Boiler controls eliminate costly on-off cycles and improve turndown ratios, saving money and extending the life of the boiler.

We house the complete line of Siemens Burner Controls and utilizes Siemens PLCs for coal-fired control solutions. EPS provides installation, commissioning, and servicing for all boiler control systems.

Siemens Controllers

Siemens controllers offer fully integrated control in a single module, saving valuable floor space over non-integrated systems. Each system is designed to meet or exceed the reliability and safety requirements of the industrial heating industry.

Our systems are easily integrated into any burner or boiler solution, removing the restrictive nature of other solutions and systems on offer. Parts and upgrades are readily available from any reputable source worldwide, eliminating costly limitations posed by other exclusive solutions. This enables the highest possible uptime at the lowest possible cost for the foreseeable future.

Boiler Control Panel Building

Custom-designed boiler control panels are built in-house. Upon customer approval, the panels undergo rigorous testing and programming before field installation. Since the bulk of testing is completed at the workshop, the customer experiences a faster and smoother installation process with less downtime.

Boiler Spares

Aftermarket parts on demand – 24/7/365

Our industrial boiler parts department provides competitive pricing and prompt, on-time delivery. Maintaining a full inventory of common repair parts in its Alrode workshop, we ensure that clients have access to essential components to keep their operations running smoothly.

Available 24 hours a day, 365 days per year, the aftermarket parts team has a solid track record of troubleshooting problems and offering top-notch service and support, with expertise in sizing and recommending the correct equipment for various applications and needs.

Available Boiler Spares:

Boiler Components

ENERGY PARTNERS AFTERMARKET BOILER PARTS – 24/7/365

- Boiler tubes

- Cleaver Brooks rear door replacements

- Stoker spares

- Stoker links

- Grit collectors

- Ash and grit trolleys

- Coal and ash handling equipment

Valves and Regulators

ENERGY PARTNERS AFTERMARKET BOILER PARTS – 24/7/365

- Relief valves

- Control valves

- Continuous blowdown valves

- Main blowdown valves

- Water valves

- Steam valves

- Steam solenoid valves

- Gas pressure regulators

- Steam pressure regulators

- Oil pressure regulators

Gaskets

ENERGY PARTNERS AFTERMARKET BOILER PARTS – 24/7/365

- Handhole

- Manhole

- Mud-hole

Pumps and Controls

ENERGY PARTNERS AFTERMARKET BOILER PARTS – 24/7/365

- Grundfos pumps

- Level controls

- Sight glasses

Burner and Ignition Parts

ENERGY PARTNERS AFTERMARKET BOILER PARTS – 24/7/365

- Burner parts

- Ignition transformers

Instrumentation and Monitoring

ENERGY PARTNERS AFTERMARKET BOILER PARTS – 24/7/365

- Pressure gauges

- Steam traps

Fans and Air Handling

ENERGY PARTNERS AFTERMARKET BOILER PARTS – 24/7/365

- ID fans

- FD fans

- SA fans

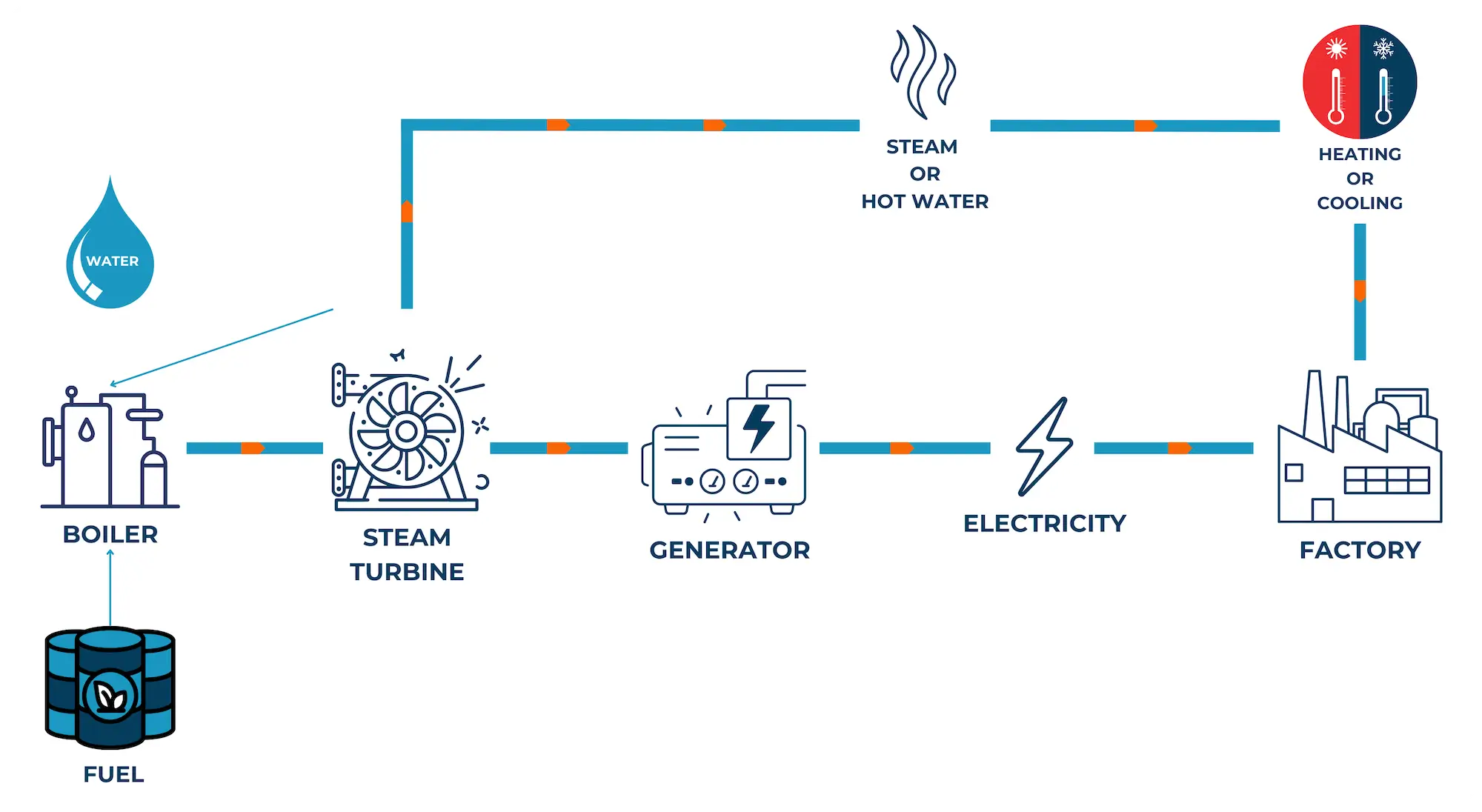

We are committed to revolutionising the energy landscape through innovations like cogeneration, employing technologies such as steam turbines and Organic Rankine Cycle (ORC).

Cogeneration, or combined heat and power (CHP), is a highly efficient technology that uses a single energy source to simultaneously generate heat and electricity, both of which are used.

- More cost effective, using less fuel and less units to meet demand

- Highly efficient, achieving energy efficiencies of up to 80%, compared to 40% for the separate generation of heat and power

- Produces less greenhouse gas emissions through the use of renewable fuels

- Offers a reliable, continuous supply of power and heat, even during grid outages

- Suitable for a wide range of applications, especially where there is a high power demand and low heat requirement.

We design bespoke cogeneration systems tailored to a facility’s energy demand:

- Comprehensive project design and consultation for optimal performance

- Management of the complete life cycle of the cogeneration project, including installation, commissioning, maintenance and operation

- Continuous monitoring and optimisation for peak efficiency and minimal waste

- Seamless integration with existing infrastructure.

Burner Spares

We maintain a comprehensive range of high-quality, critical industrial burner spare parts, ensuring that our clients have the components they need to keep their operations running smoothly.

- Extensive inventory

- Durable, genuine top-quality components sourced from reputable manufacturers

- Competitive pricing

- Expert technical support

- Customised solutions tailored to client requirements

- Efficient, timely delivery and quick turnaround times.

Our Burner Suppliers

We are the exclusive Southern African representatives and distribution partners of Unigas.

- Wide range of burners from 15 to 70 000 kW

- Custom-made burners made to meet specific requests

- Known for low NOx emissions, high turndown ratios and easy maintenance.

We are the exclusive Southern African representatives and distribution partners of Greens Combustion burners.

- Advanced technology assures high-performance, low-noise and low-fuel-consumption burners

- Suitable for a wide range of applications, including kilns, incinerators, refineries, top fired reformers, radiant wall furnaces and EDC crackers

- Ideal for clients who require high-temperature and high-pressure combustion.

We are the exclusive partner of CPF Industriale, Geca and Tecnocontrol in South Africa.

- Regulates gas pressure and flow for a stable and consistent supply of gas to burners, boilers or heaters

- Filters gas quality, removing impurities or contaminants that could damage the equipment or affect the combustion

- Protects gas systems from overpressure and underpressure, preventing accidents or malfunctions

- Suitable for various applications, such as burners, boilers, heaters, furnaces, ovens, dryers and generators

- Saves energy and reduces emissions, by ensuring optimal combustion and minimising gas wastage.

This comment is pinned to a missing element.

We provide comprehensive solutions for burner projects, including package, process, gas and oil burners.

Our expertise encompasses:

- Installation

- Performance optimisation

- Inspections

- Maintenance, call-outs and repairs.

We partner with industries to design, install and maintain burner systems that meet specific operational requirements, ensuring efficiency and reliability.

Industries we serve:

Manufacturing

Precise temperature control for curing, drying, and heat treatment, optimising combustion efficiency, and ensuring product quality while reducing energy costs.

Food Processing

Accurate heating for cooking, pasteurisation and sterilisation to prevent undercooked or overcooked products, meeting safety and quality standards.

Chemical Industry

Ensures safety and precision by controlling temperatures in chemical reactions, reducing accidents and ensuring product consistency.

Textile Industry

Precise temperature control for dyeing and finishing processes reduces energy costs and enhances product quality.

Healthcare

Vital for reliable and consistent steam supply, critical for sterilisation and maintaining high hygiene and safety levels.

Why Energy Partners?

Customised Solutions

- We tailor burner projects to meet clients’ specific needs, offering a wide range of burner products from Unigas and Greens Combustion, two of the leading brands in the market.

- We also source and sell any other make of burner as needed.

Performance Optimisations

- We use state-of-the-art tools and methods to monitor and adjust the burner parameters, improving burner performance for higher efficiency, better reliability and reduced operational costs.

- We provide regular inspections and maintenance to ensure optimal combustion conditions and prevent breakdowns.

Emergency Support

- Our team of qualified and experienced technicians are available 24/7 to ensure rapid response to call-outs and repairs to minimise production disruptions. We also stock spare parts and consumables for quick replacement.

Efficiency

- We can help clients achieve the highest possible burner system efficiency by selecting the best fuel type and burner model for client applications, installing proper controls and sensors, implementing heat recovery systems, and providing regular audits and recommendations.

- By improving efficiency, clients save fuel costs, reduce emissions, extend equipment lifespan, and increase productivity.

We are the exclusive Southern African representatives and distribution partners of Unigas.

- Wide range of burners from 15 to 70 000 kW

- Custom-made burners made to meet specific requests

- Known for low NOx emissions, high turndown ratios and easy maintenance.

We are the exclusive Southern African representatives and distribution partners of Greens Combustion burners.

- Advanced technology assures high-performance, low-noise and low-fuel-consumption burners

- Suitable for a wide range of applications, including kilns, incinerators, refineries, top fired reformers, radiant wall furnaces and EDC crackers

- Ideal for clients who require high-temperature and high-pressure combustion.

Why choose servitisation?

Servitisation is a shift from ownership to usership, where clients pay for the output or outcome of the burner system, rather than buying the equipment itself.

Our service-based options enhance client competitiveness and reduce risk.

Clients can choose from two levels of servitisation:

- Service level agreement (SLA): We provide a comprehensive and customized plan that specifies the frequency, scope, and quality of the service that we will deliver.

Clients benefit from:-

- Reduced downtime

- Improved performance

- Lower operational costs.

-

Performance Optimisations

- Servitised option: We charge for the results that clients need, rather than the equipment itself. We take care of the ownership, operation, maintenance, and upgrade of the burner system.

Clients benefit from:-

- Lower upfront costs

- Predictable cash flow

- Improved availability

- Guaranteed performance.

-

Servitisation also aligns our interests with clients’, as we are incentivised to keep the burner system in optimal condition, prevent any major breakdowns, and ensure its safe operation.

The cost of fuel makes up more than 99% of the total lifetime cost of using burners. Proper maintenance and efficiency optimisation can result in significant savings on even small common burner sizes. This effect, and the subsequent need for partnership with highly experienced specialists in burners is pronounced when considering any large-sized solutions.

Most commonly sold small burner with average maintenance

Large burner with average maintenance

Our multidisciplinary engineering team delivers bespoke and reliable steam solutions, using proven and innovative methods to support the driving power of our clients’ businesses.

- We design engineering solutions with a long-term business case mindset, customising them for the highest efficiency without compromising on safety

- Our design process is environmentally conscious, while also focused on providing clients with a high degree of reliability.

We utilise cutting-edge design tools, such as:

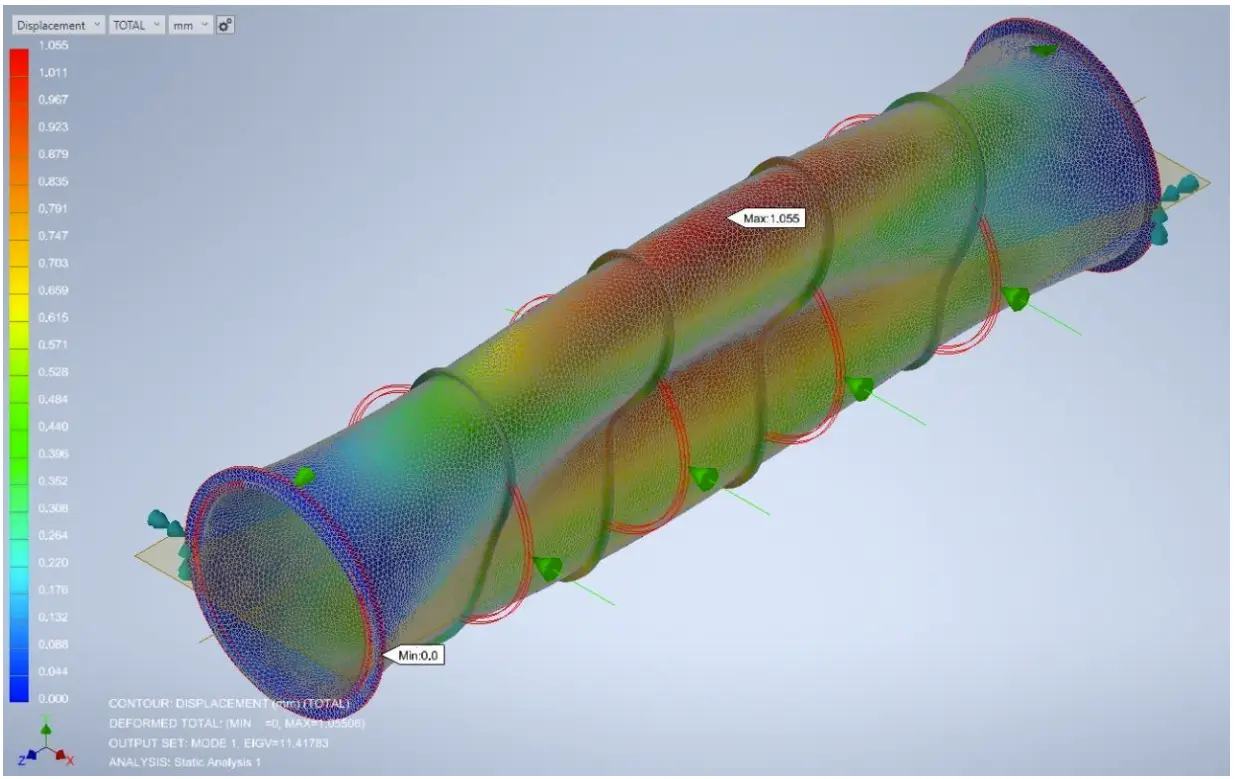

- 3D computer-aided design with finite element analysis and computational fluid dynamics

- Advanced calculations to comply with design standards and first principles. This includes detailed knowledge of ASME, EN and ISO design standards

- Remote support and diagnostic data capturing capabilities for boilers with the Optiflame control systems

- Product selection to match the process with hardware that delivers the optimum system.

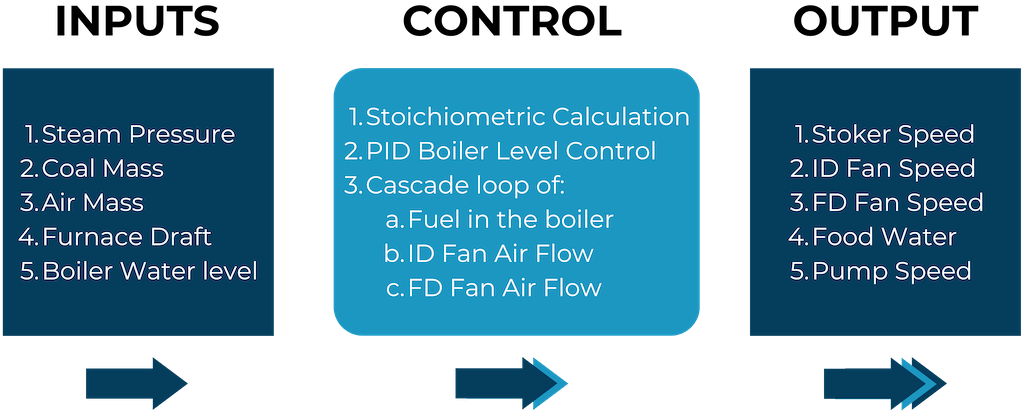

What is the Optiflame control system?

Optiflame is a control system that optimises the life cycle cost of boiler house equipment.

Developed by Energy Partners, Optiflame is the result of our experience in owning and operating energy assets, our culture of innovation in pushing the boundaries of efficiency and reliability, and our significant track record in achieving results.

Optiflame achieves:

- Steam pressure control

Experience a stable steam supply under varying operating load condition.

- Boiler efficiency

Boiler efficiency is primarily driven by control of excess air (air-fuel ratio). Using frequency inverters and electronic fuel trim control, coal usage is reduced, typically to between 8% and 15% when compared to electro-mechanical or manual control systems.

- Boiler preservation

Motors run much slower, and less coal is burnt, reducing maintenance and increasing economic life expectancy.

- Environmental impact

With less coal burnt and less electricity used, Optiflame ensures that less harmful emissions are released into the atmosphere. Additionally, proper excess air control minimises the release of NOx and CO emissions into the atmosphere.

- Elimination of human intervention

Decision making becomes the function of a programmed steam production process, where the response to changes in steam supply conditions are immediate and consistent, significantly reducing the human factor in boiler operation.

Optiflame is coupled with the Energy Partners Oxygen Sensor, which too was developed by our team, and enables the control system to trim boiler controls to the optimum combustion setpoint.

Energy Partners’ Optiflame steam boiler control process

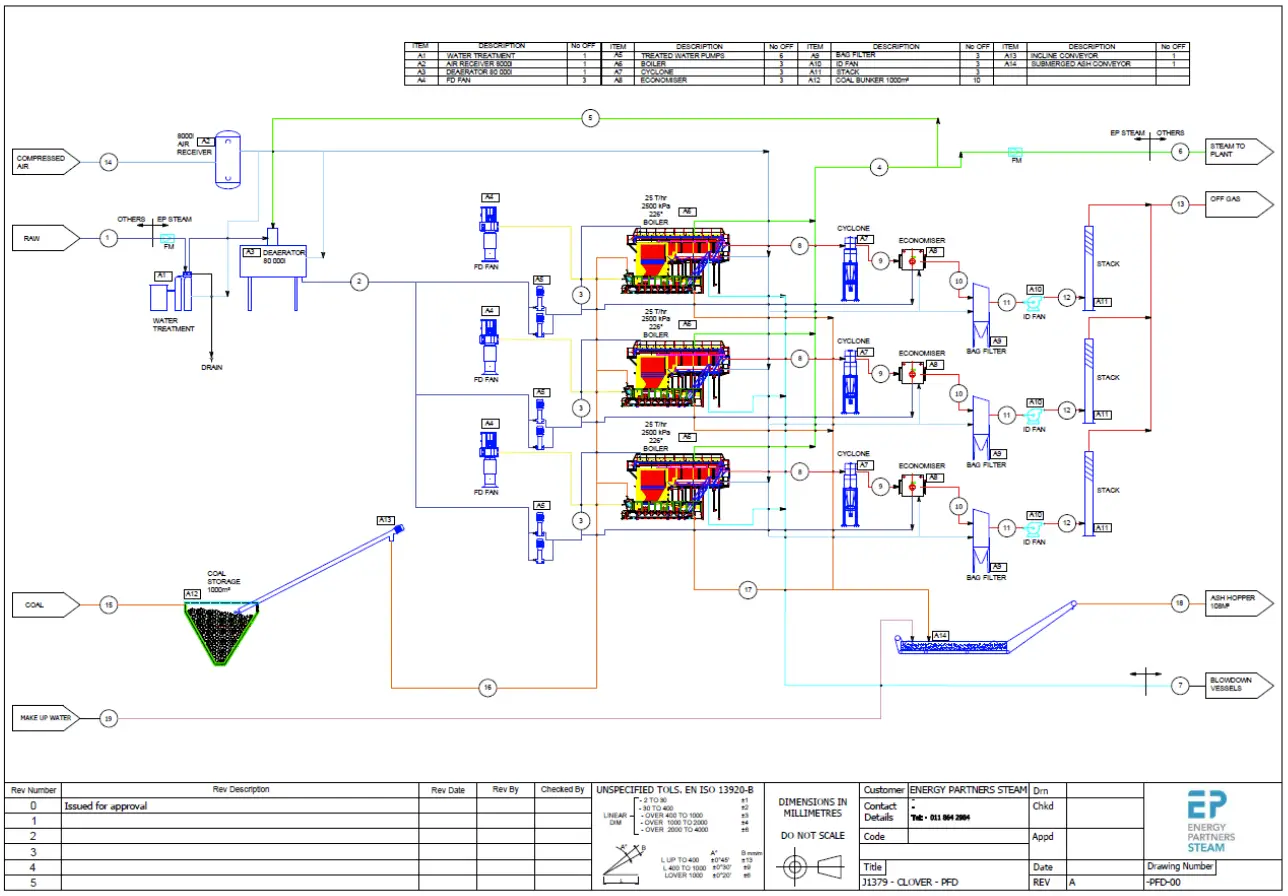

Steam system process flow

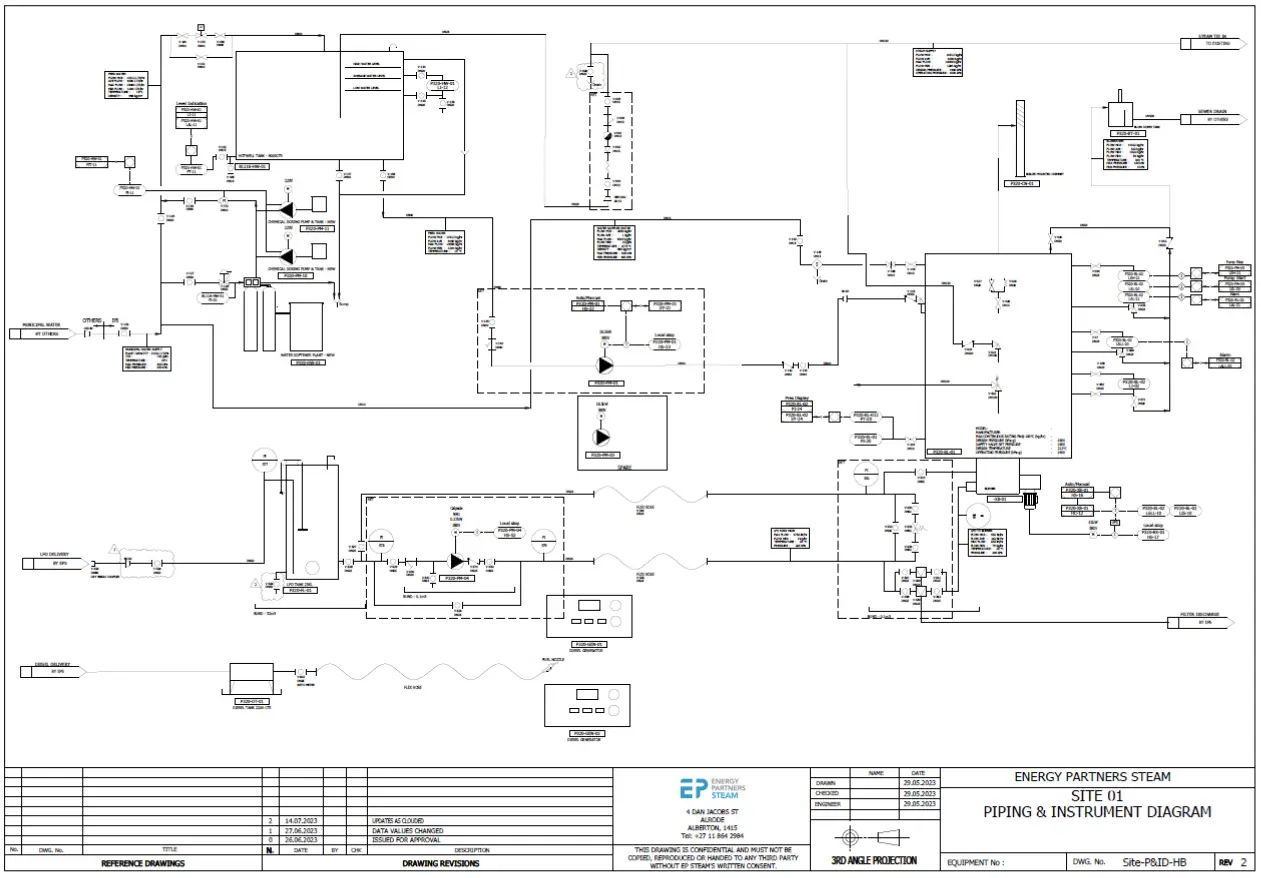

Piping and instrumentation

Non-liner FEA analysis of a boiler flue

About Us

Energy Partners Steam has been a going concern since 1958, first as The Ernest Dryden Co. (Pty) Ltd., then The Dryden Combustion Company (Pty) Ltd and now Energy Partners Steam, a division of Energy Partners Holdings (Pty) Ltd., with a very strong brand association in South Africa.

Dryden Combustion History

In 1945 Ernest Dryden flew from Durban (Flying Boat) to negotiate with the owners of Daniel Adamson of Dunkfield, Cheshire, England, for representation in Southern Africa. This company was in a unique position being able to manufacture a complete power station in their own works, viz. Water Tube Boilers and Turbo Alternators.

On his return to Johannesburg, a company was formed and titled THE DRYDEN DANADAMSON CO. (PTY) LTD. This company was on a 50% share basis. After trading for about four years they were successful in obtaining some very substantial orders for Watertube Boilers for East London Power Station, through Merz & McLellan. They also received orders for boilers and turbo alternators for Kroonstad and Cradock Power Stations. As most of this supply would have to come from Daniel Adamson at Dunkinfield, it was decided to form another company DANIEL ADAMSON (AFRICA) (PTY) LTD. Again, on a 50% basis, the original company to carry on with Underfeed Stokers, Dutchovens, amongst others.

When Daniel Adamson was taken over in 1958, there was an option of buying the remaining shares and the name changed The Ernest Dryden Co. (Pty) Limited.

Initial involvement was in the supply of water tube boilers at (amongst others) Theisen Marine. Although the company has subsequently closed, the chimney stacks have been preserved from the original boilers and can be seen on Theisen Island in Knysna today.

In 1988 the company was purchased from the Dryden family by Gordon Slater and Sue Kiley. The new owners changed the company’s focus from water tube boilers to coal, oil and gas fired packaged steam boilers. Dryden Combustion has developed into the market leaders in their field. The company has supplied boilers not only to South Africa and neighbouring states but has also exported to countries such as Poland and China.

Dryden Combustion’s renowned heritage and trusted name has been strengthened through its acquisition by Energy Partners. As part of the PSG group, we acquired Dryden Combustion in 2017 and re-branded it to Energy Partners Steam.

Although the name has changed, the company’s commitment to service and product quality remains steadfast. Backed by over 60 years’ industry experience and ISO 9001 accreditation, we are dedicated to lowering the cost of steam by minimising downtime and optimising efficiency. With its vision to be the leading provider of steam solutions in Southern Africa, we focus on delivering value and reliability to clients, backed by our team of highly skilled engineers, installation crews and trusted partners.